Samaynta magnet Alnico giraanta

Sharaxaada Alaabta

Alnico magnet waa daawaha ka samaysan aluminium, nikkel, cobalt, copper, birta iyo alaabta kale. Sida laga soo xigtay tignoolajiyada processing ee kala duwan, waxa loo qaybin karaa alnico tuuray iyo sintering alnico.

Qaadista alnico waxay leedahay hanti birlabeed sare leh waxaana loo habayn karaa cabbirro iyo qaabab kala duwan.Sintering alnico waxay leedahay hab fudud waxaana si toos ah loogu cadaadin karaa cabbirka loo baahan yahay.

Faa'iidada alnico magnet waa in isku-dhafka heerkulku uu yar yahay, sidaas darteed hantida magnetic ee ay keento isbeddelka heerkulka aad ayuu u yar yahay. Heerkulkeeda ugu sarreeya wuxuu gaari karaa 400 darajo Celsius. Waqtigan xaadirka ah, waxaa si ballaaran loo isticmaalaa qalabka, qalabka iyo alaabta kale ee u baahan. xasilloonida heerkulka sare.

Iska caabinta daxalka ee AlNiCo magnet waa mid xoogan.

Sharaxaada Alaabta

| Magaca Alaabta | Magnet-qaadista gitaarka ee loo habeeyay Alnico 2/3/4/5/8 magnet soo qaadis |

| Qalab | AlNiCo |

| Qaab | Usha/Bar |

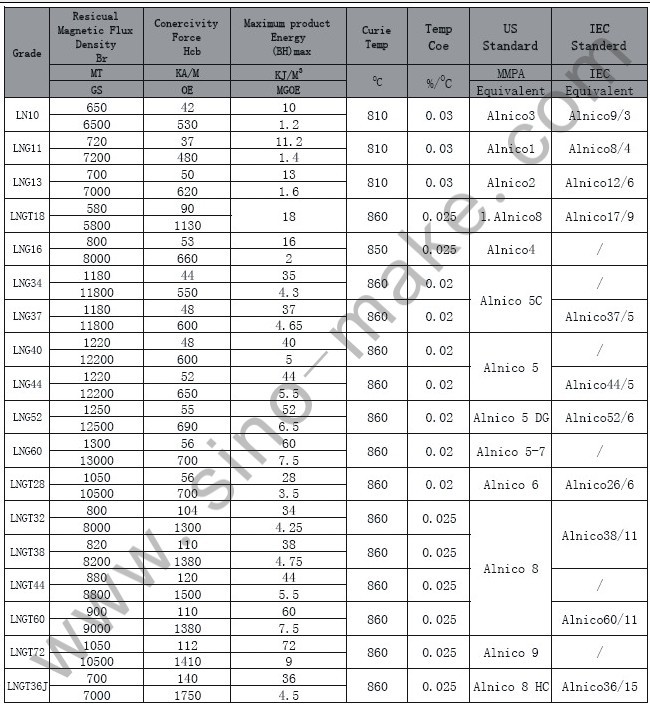

| Darajo | Alnico2,3,4,5,8 |

| Heerkulka shaqada | 500°C ee Alnico |

| Cufnaanta | 7.3g/cm3 |

| Tusaale | Bilaash |

| Baakad | Magnet+ Kartoon Yar Oo+Damac Xumbo+Bir+Kaartoon Weyn |

| la isticmaalo | Goobta Wershadaha/Guitar waxay soo qaadaa magnet |

Baakad & Gaadhsiin

Baakad:

Maaddaama magnets-ku leeyahay soo jiidasho xooggan, waxaanan isticmaali doonaa spacer-ka si aan u kala saarno birlabadaha midba midka kale haddii ay dhacdo in dadku ay dhaawacmaan marka la soo saaro.Kadibna, waxaa lagu soo rari doonaa sanduuq cad oo midkiiba, dhowr sanduuq oo kartoon ah.

+ By Hawo Haddii alaabta lagu soo rari doono hawo, dhammaan magnets-ka waa in hawada laga saaro oo waxaan adeegsan doonaa xaashida lron si aan u difaacno.

+ Badda: Haddii badeecada lagu soo rari doono badda, waxaan dhigeynaa baakad gunta hoose ee kartoonnada.

Bandhiga Alaabta

QAAB

Aqbal habaynta macaamiisha, qaabab kala duwan si aad u buuxiso dhammaan shuruudaha macaamiisha.